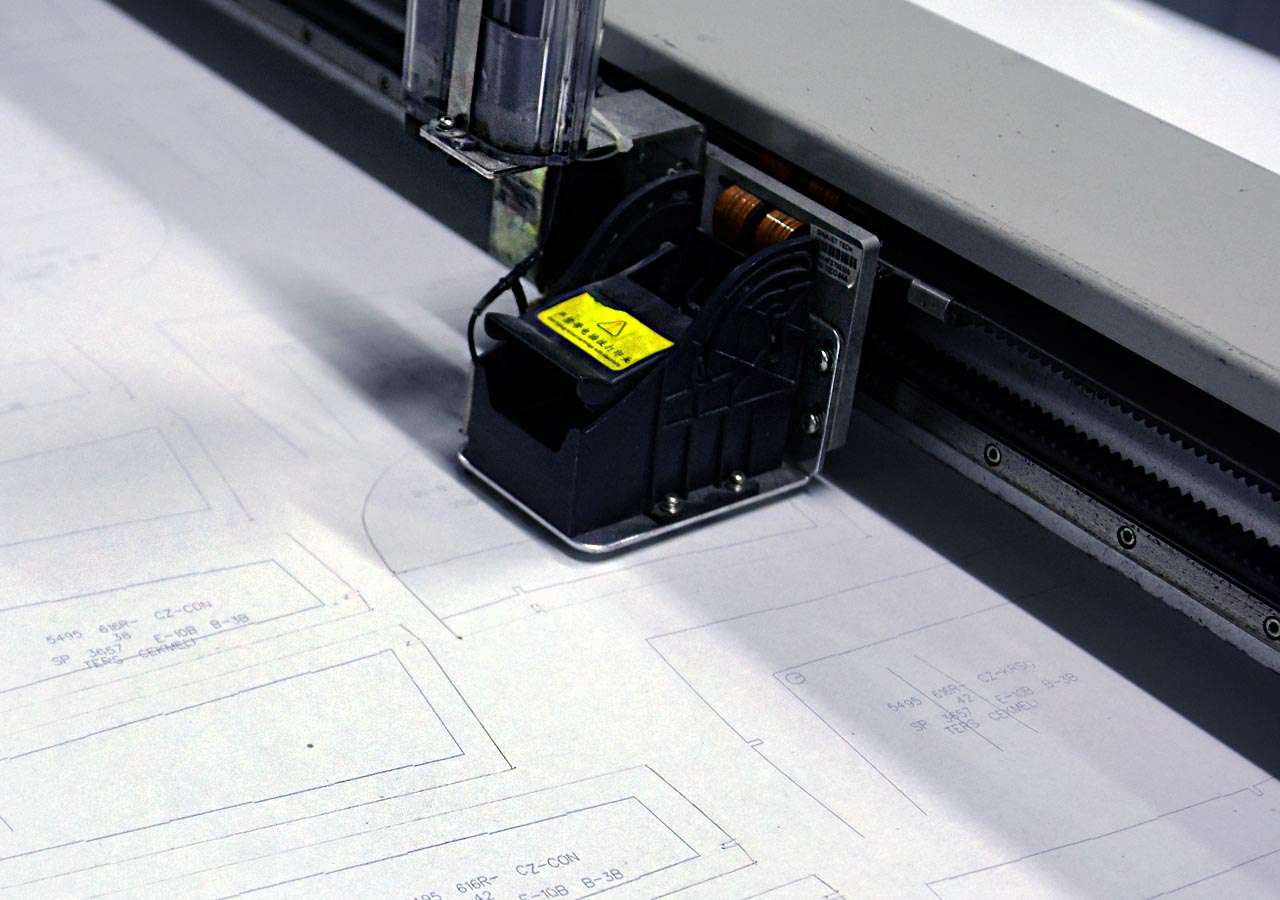

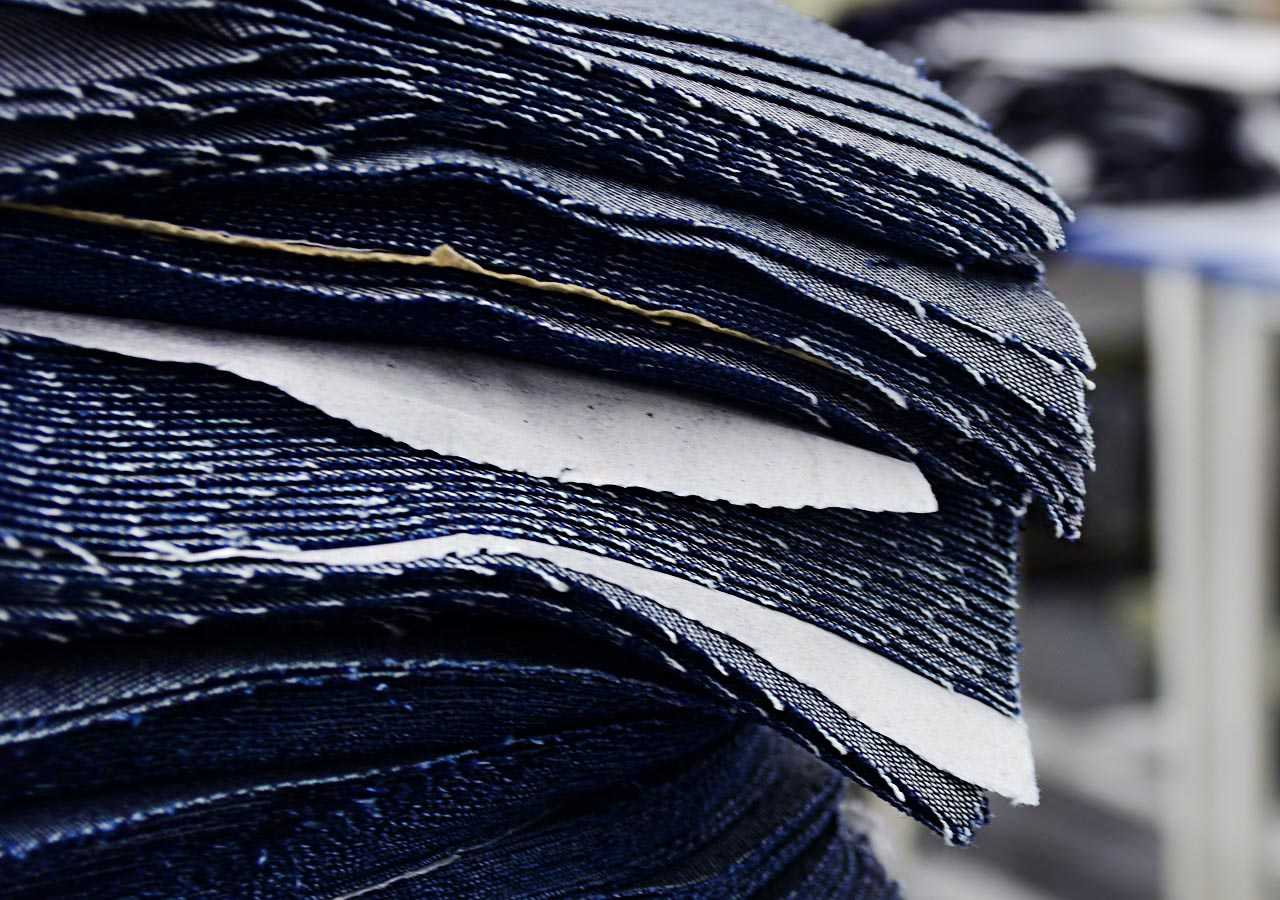

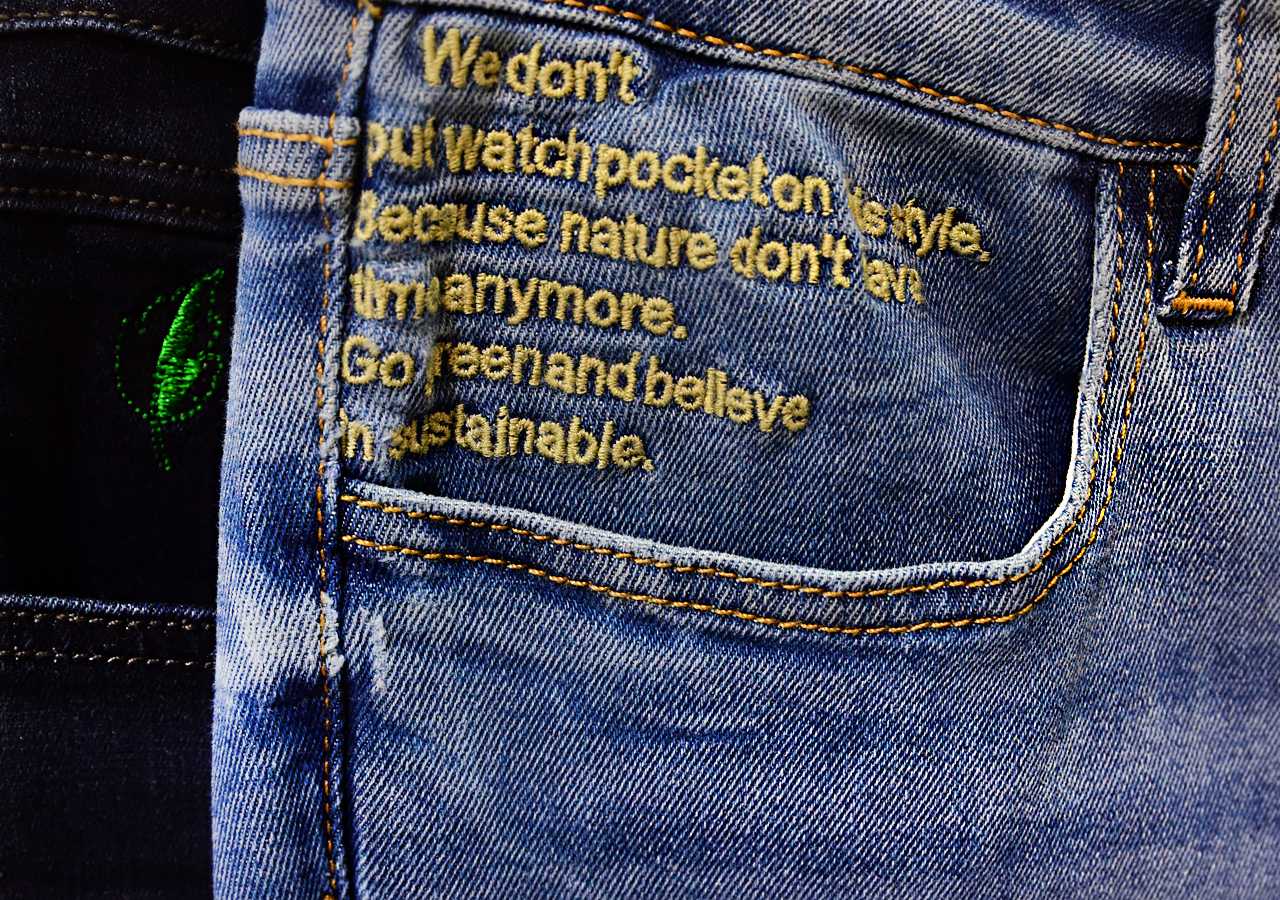

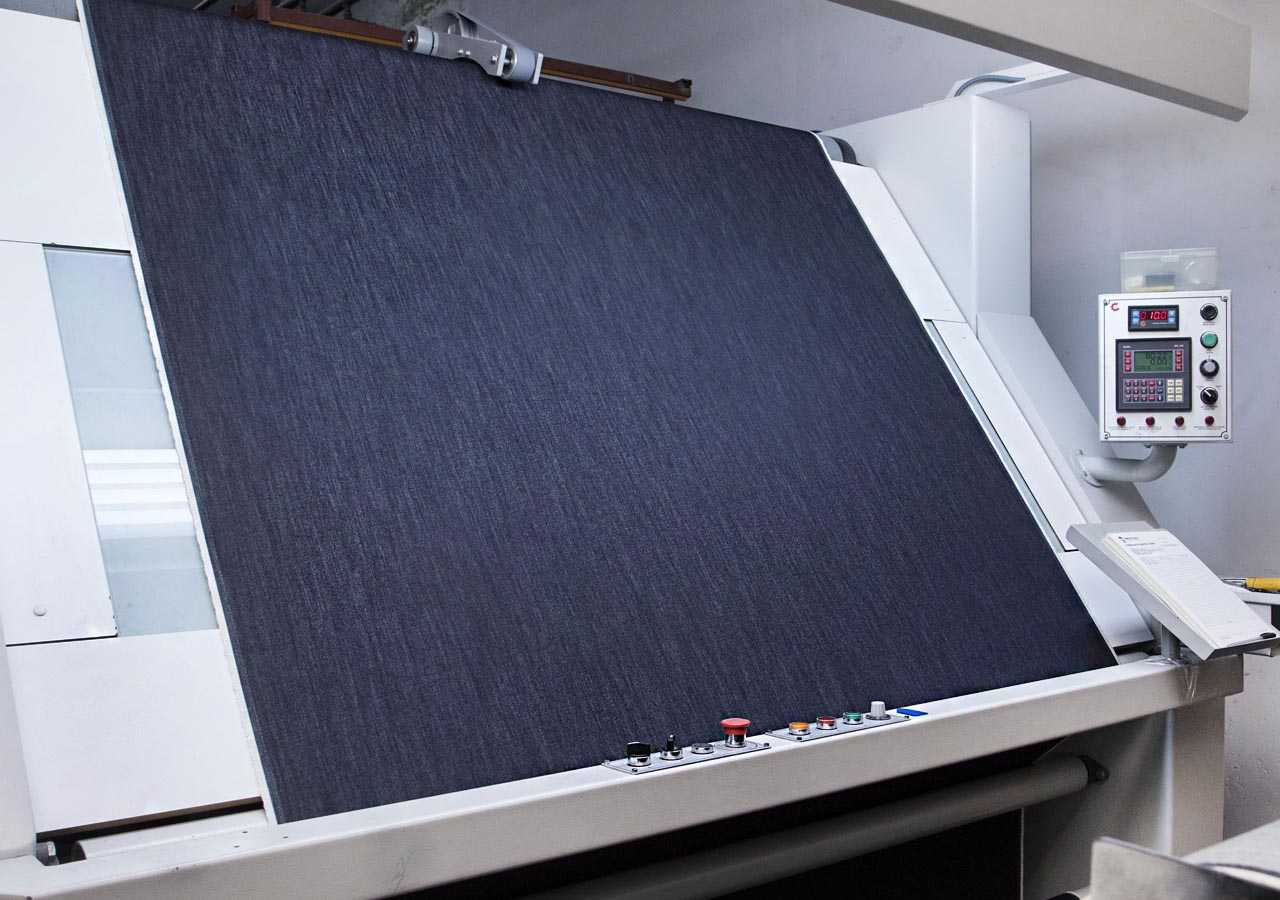

In our production and laundry facility in Istanbul Günesli with 34.000 m2 and our production facility in Malatya with 10.000 m2 we produce more than 6 million denim annually with modern technologies, excellent quality control and environmental awareness.

From next year, the production facility in Çerkezköy, which is currently under construction, will also be added. It will have its own water treatment plant, in addition to the latest standards already in use, which will enable us to work with Zero Liquid Discharge certification. In this way with the launch of our new factory, we aim to increase our production capacity and reduce our carbon footprint.

Now, let's take a closer look at the Merkoteks production facilities, which host the productions of world brands.